The insulating glass is a glass deep-processed product in which two or more sheets of flat glass are separated by a partition frame and sealed with a sealant to form a dry gas space between the glass layers. It should be noted that the edge of the insulating glass is tightly sealed with a sealant. The inner cavity of the insulating glass is filled with dry air or an inert gas. The part of the gas is sealed in the cavity for a long time and cannot convect with the outside air. Therefore, The heat on both sides of the insulating glass does not take away heat due to the convection of the gas between the glass. On the other hand, air is a poor conductor of heat, and the two layers of glass separated by a sealing gas have little heat conduction with each other, thereby providing good heat insulation. In addition, when a large temperature difference occurs on both sides of the insulating glass, since one glass only feels the temperature on one side, the two surfaces of the single piece of glass do not have a large temperature difference. Therefore, when the temperature difference between the inside and the outside of the insulating glass is not particularly large (≥100 ° C), no frosting or dew condensation occurs. In addition, there is one point to be explained is that hollow glass is not vacuum glass, hollow glass gas pressure is basically the same with the outside world, otherwise it is very easy to cause the glass broken.

From the above explanation, it can be known that there is an essential difference between the insulating glass and the ordinary double glazing. The most essential difference between the two is that the former is sealed and the latter is not sealed. It is precisely because of the unsealing of double-glazed glass that dust and water vapor can easily enter the inner cavity of the glass. When the water vapor is cold and frosted, the dust adhering to the inner surface of the glass can never be removed, and the window will be cleaned soon after installation. The glass is blurred and filthy. Of course, double-layer glass can also play a certain role in sound insulation and heat insulation, but the performance is far from the hollow glass.

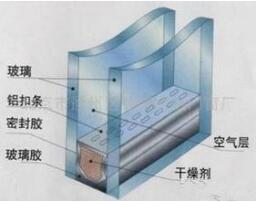

The hollow glass construction generally refers to a sealed structure of an insulating glass. There are two main sealing structures for insulating glass: single-channel sealing and double-channel sealing. The single-pass sealing structure means that only one glue is used for the hollow glass structure, and silicone rubber, polysulfide rubber, polyurethane, hot melt butyl rubber or comfort rubber strip can be selected. The double-pass sealing structure refers to the two-layer glue of the hollow glass structure, usually using polyisobutylene rubber as the first sealing and the structural adhesive such as polysulfide or silicone rubber as the second sealing. In general, in the two-pass sealing system, the glue used for the first seal has high water vapor transmission rate but poor structural properties, while the second sealant has high structural performance and poor water vapor transmission resistance.